Emanuele Cannella works as an Early Stage Researcher (ESR) of the MICROMAN project, under the supervision of Associate Professor Chris Valentin Nielsen, Professor Niels Bay and IPU Chief Operating Officer (COO) Anette Rasmussen. The industrial partner is a Danish company working in the field of powder metallurgy.

His focus is on the tool design, process optimization and sample characterization for Electro Sinter Forging (ESF) of components. This process is suitable as an alternative for manufacturing small components made of conductive metals, e.g. titanium. Starting from a powder state, the raw material is compacted inside a closed die and then a high electric current flows through the “green compact” to generate bonding among the particles. Components are manufactured within few seconds, decreasing the risks connected to oxide contamination and grain growth.

Main applications of this process are on the medical, electrical and mechanical sectors, e.g. micro gears. Complex shapes can be realized in a reduced amount of time by shaping the powder in a proper electrically insulated die.

“The MICROMAN ITN provides me high level tools to succeed in my research, by giving me very useful workshops and activities which made me develop in the past years. Meeting and sharing knowledge with the other ESRs are highly stimulating to develop new ideas”, says Emanuele.

Emanuele recently published a poster at the 18th International euspen Conference and Exhibition, where he discussed on the process optimization for ESF in the case of small discs made of titanium powder (Available at: http://orbit.dtu.dk/ws/files/149116924/euspen_poster_for_Orbit.pdf). Other studies concern the application of ESF for sintering a magnetic alloy based on neodymium and testing new shapes, e.g. rings, to be used as rotors for small electrical engines.

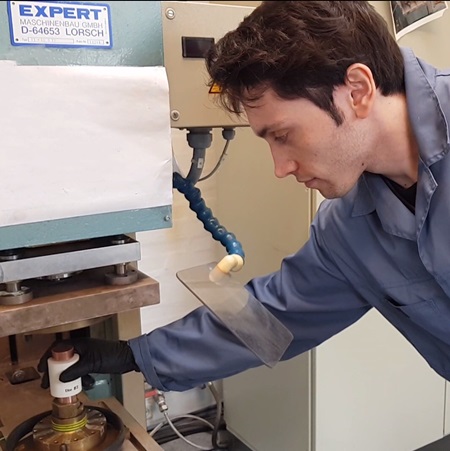

Emanuele while operating the MFDC EXPERT D-64653 resistance welding machine during his sintering activities at DTU MEK.